Crafting the World’s Smartest Hardscape Products

Choices abound when creating beautiful outdoor spaces with Rosetta, so why wouldn’t producing it offer just as many options?

One-Size-Fits-All? Nope.

Your success means our success. So you won’t be limited to one or two manufacturing avenues. Instead, we’ll work with you to design a production process that will work for you. Learn about the different start-up strategies you can utilize to grow your Rosetta production at your pace and scale

Manual Production

Where most new manufacturers start, the manual production process is simple, straightforward, and supremely scalable. Manual production can be smoothly transitioned into an efficient, high-volume automated process.

Semi-Automated Production

Automation can be your start or your destination since the equipment necessary for the manual process is integrated into the automated process. Automating production can help you control labor costs, satisfy increasing demand, and add extra quality control measures.

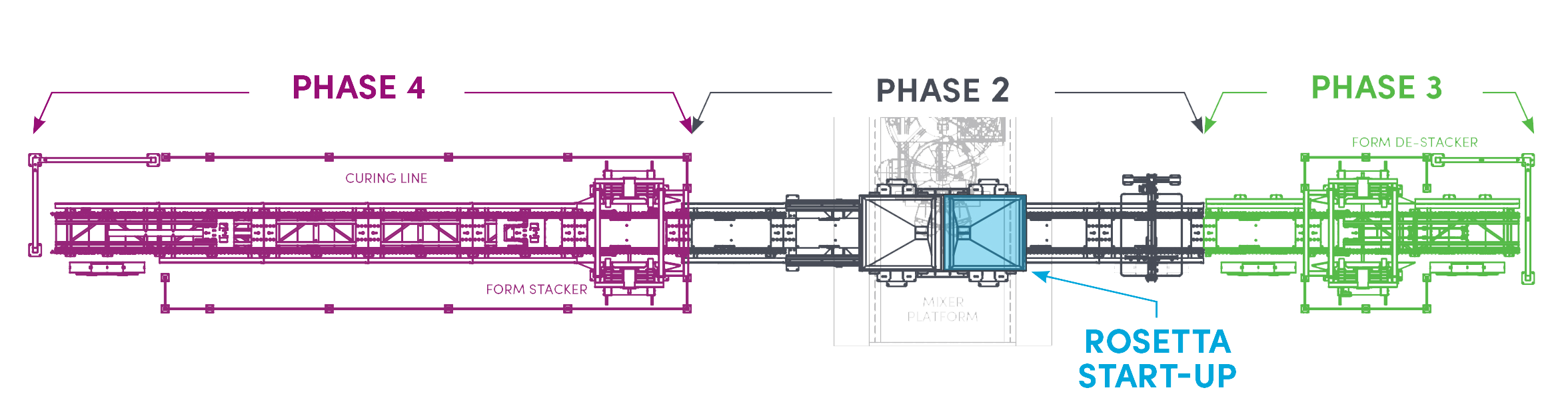

Rosetta Start-Up

Start with manual production and easily transition to partial or full automation. Or come out of the gates with a fully automated manufacturing process. Either way, you won’t be going it alone since our team of operations experts will help you build a production plan tailored to your needs and goals.

Rosetta Start-Up

- Vibrating Table

- Grout Hog or Mobile Hopper

Phase 2

- Hopper Structure and Funnel

- 2 Mobile Hoppers

- Vibrating Table

- 3 Station Latch Conveyor

- Hydraulic Power Unit (5 HP)

- Fork Lift Bumpers

Phase 3

- Form Destacker

- 5 Additional Stations of Latch Conveyor

- Hydraulic Power Unit (30 HP)

- 2 Extra Fork Lift Bumpers

Phase 4

- Stacker

- Curing Conveyor (6 stations including transfer station in stacker)

- Hydraulic Power Unit (30 HP)

- 3 Extra Fork Lift Bumpers

Build Your Equipment Package

Now that you’re familiar with the production process, share your Rosetta vision with us!

FAQ

What other production equipment do I need?

Rosetta Hardscapes production is scalable based on your plan and resources so equipment investment can be flexible. Beyond forms and molds, start-up manual production generally demands a fork lift, a vibrating table, and a grout hog or mobile concrete hopper. Additional equipment like conveyors, fork lift bumpers, form stackers and destackers, and hydrolic power units can be easily added to create an automated production line and meet increased product demand as your market grows.